FORGINGS, CASTINGS & INVESTMENT CASTINGS

FORGINGS

INVESTMENT CASTINGS

METAL CASTINGS

Forging, in a manufacturing context, is a process where metal is shaped by compressive forces, typically through hammering or pressing. The metal is often heated before shaping, though it can also be done cold. Forgings refer to the finished, shaped metal parts produced through this process. Elaboration:

- Shaping with Compressive Forces: F

Forging, in a manufacturing context, is a process where metal is shaped by compressive forces, typically through hammering or pressing. The metal is often heated before shaping, though it can also be done cold. Forgings refer to the finished, shaped metal parts produced through this process. Elaboration:

- Shaping with Compressive Forces: Forging involves using force to compress the metal, either with a hammer or a die press, to create the desired shape.

- Heating (Optional):Metal is often heated before forging to make it more pliable and easier to shape, a process known as hot forging. Cold forging, where the metal is shaped at room temperature, is also possible.

- Forgings: The resulting shaped metal pieces are referred to as forgings. These can be anything from small, intricate components to large, heavy structures.

- Grain-Oriented Strength: Forgings are often grain-oriented, meaning the metal's grain structure is aligned with the direction of shaping, which enhances the strength of the part.

- Examples: Forgings are used in a wide range of applications, including automotive parts, aircraft components, and industrial machinery.

METAL CASTINGS

INVESTMENT CASTINGS

METAL CASTINGS

Metal casting is a manufacturing process where molten metal is poured into a mold to create a solid, three-dimensional object. The metal cools and solidifies within the mold, taking the shape of the cavity. This process is used to produce various parts and objects, from small jewelry to large industrial components. Key aspects of metal c

Metal casting is a manufacturing process where molten metal is poured into a mold to create a solid, three-dimensional object. The metal cools and solidifies within the mold, taking the shape of the cavity. This process is used to produce various parts and objects, from small jewelry to large industrial components. Key aspects of metal casting:

- Molten Metal: The process begins with heating a metal to its liquid state.

- Mold: A cavity or shape is created within a mold, typically made of sand, die, or ceramic.

- Pouring: The molten metal is poured into the mold to fill the cavity.

- Solidification: The metal cools and solidifies, taking the shape of the mold.

- Removal: The solidified metal object, or casting, is removed from the mold.

- Finishing: The casting may be further processed, such as deburring, machining, and finishing.

Types of metal casting:

- Sand Casting: A traditional method using sand as the mold material.

- Die Casting: Molten metal is injected into a reusable steel mold under high pressure.

- Investment Casting (Lost Wax Casting): A wax pattern is used to create a mold, and then the wax is melted away before pouring the molten metal.

- Centrifugal Casting: The mold is rotated while molten metal is poured in, allowing for uniform thickness and density.

- Shell Molding: A thin-walled mold is created using a sand-resin mixture, offering good accuracy and productivity.

INVESTMENT CASTINGS

INVESTMENT CASTINGS

INVESTMENT CASTINGS

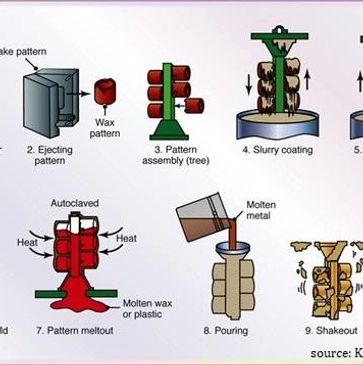

Investment casting, also known as lost wax casting, is a metalworking process where a wax pattern is used to create a mold for producing a metal casting. This technique is favored for its ability to create complex shapes with high precision and fine surface finishes. Here's a more detailed explanation:

- Wax Pattern Creation: A wax pattern,

Investment casting, also known as lost wax casting, is a metalworking process where a wax pattern is used to create a mold for producing a metal casting. This technique is favored for its ability to create complex shapes with high precision and fine surface finishes. Here's a more detailed explanation:

- Wax Pattern Creation: A wax pattern, identical to the desired casting, is created using injection molding or other techniques.

- Mold Creation: The wax pattern is coated with a ceramic slurry, which is then allowed to dry and harden, forming a mold.

- Pattern Removal: The wax pattern is melted out, leaving a void in the ceramic mold.

- Metal Pouring: Molten metal is poured into the ceramic mold to fill the void.

- Solidification: The metal cools and solidifies within the mold.

- Mold Removal: The ceramic shell is broken or blasted away to reveal the finished metal casting.

Advantages of Investment Casting:

- Precision and Accuracy:Investment casting allows for the creation of parts with very tight tolerances and fine details.

- Complex Shapes:It can produce intricate shapes that would be difficult or impossible to achieve with other casting methods.

- Smooth Surface Finish:The resulting castings often have a smooth, near-net-shape finish, requiring minimal or no post-machining.

- Thinner Walls:Investment casting can produce castings with very thin walls.

- Versatile Materials:It can be used to cast a wide variety of metals, including stainless steel, nickel-based alloys, and superalloys.

Limitations:

- Cost: Investment casting is generally more expensive than other casting methods like sand casting due to the complex processes involved.

- Lead Times: Longer lead times may be required due to the specialized nature of the process.

- Size Limitations: Investment casting is not ideal for producing very large parts.

Applications:Investment casting is used in various industries, including:

- Aerospace: Turbine blades, engine components.

- Medical: Implants, surgical instruments.

- Industrial: Pumps, valves, gears.

- Firearms: Components, receivers.

- Jewelry: Intricate designs.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.